Qingdao Teste Metal Products Co., Ltd.

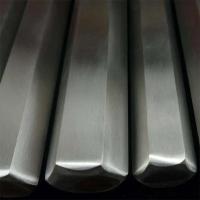

Qingdao Teste Metal Products Co., Ltd. is a professional

manufacturer with more than 20 years of experience in manufacturing

stainless steel and carbon steel establised in 2018. Our location

is in Wuxi - the largest stainless-steel processing center in

China.

We have our own factory and provide a one-stop service for cutting,

forming and surface processing of metal products.

Also we cooperate with TISCO,CHENGDE,TSINGSHAN,DELONG,YONGJIN,

HONGWANG,JISCO,QPSS, POSCO-ZPSS and ESS.